SHAKERAMA is a new system for dyeing laboratory samples, designed and produced by Tecnorama to complete its range of automatic dyeing machines forming part of the DOS&DYE COMPACT system.

This machine is particularly suitable for dyeing knitwear and fabric made of all type fibres: natural, artificial and synthetic.

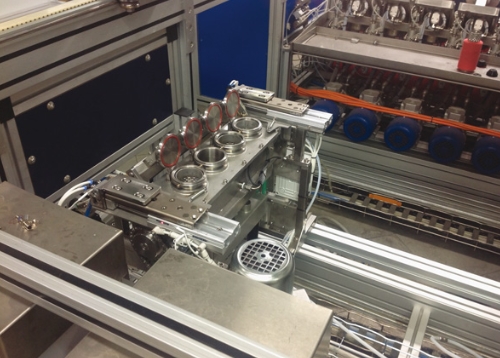

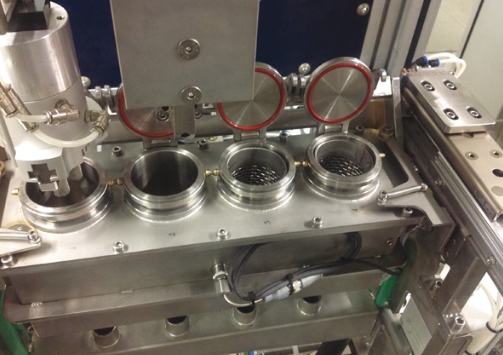

SHAKERAMA is conceived to work with groups of more autoclaves carrying out simultaneously dyeing cycles with different recipes but using the same dyeing program.

Thanks to the electric heating system it is possible to reach a max. temperature of 142°C, while the cooling system by means of a forced circulation coil with water, can bring back the temperature down to around 30°C.

With this type of heating system (bain-marie), perfect temperature uniformity and regularity is guaranteed for all dyeing units. The problem of uniformity in the dyeing unit during the dyeing process is generally encountered in the dyeing machines using Infra-Red radiant heating system, which can create big problems in terms of dyeing reproducibility.

The name SHAKERAMA means the system chosen to “shake” the liquor and move the textile material, so as to ensure uniform dyeing processes, with liquor ratios as low as 1:5.

As already mentioned, SHAKERAMA has been devised to form part of the well known DOS&DYE COMPACT system, thus it works completely independently and automatically. This machine particularly consists of:

- An automatic system for opening/closing dyeing units

- Automatic loading/unloading of the textile material

- Automatic draining of the dye liquor

- Heating and cooling operations, controlled by dedicated software

This machine, in combination with Tecnorama dispensing machines (DOSORAMA models), becomes a system for a full automation of the whole dyeing working cycle: dispensing of dyestuffs and chemicals, part of dyeing recipes, are inlet directly and automatically into the dyeing units by the multi-pipette dispensing system. Other chemical products can also be dispensed automatically during dyeing processes.

In other words, SHAKERAMA is an innovative dyeing machine that fits in perfectly with the "Full Automatic" philosophy of the DOS&DYE COMPACT.

The creation of SHAKERAMA marks the final element, introducing a new type of dyeing system with the “shaking” of the liquor and the textile material at the same time, similar to the working concept of the Jet and Jet-Flow dyeing machines used in bulk.